Why Powder Coating Fails – And How Refinishing Restores Your Surfaces Without Replacing?

- When Powder Coating Doesn’t Last

- Common Reasons Why Powder Coating Fails

- The Smarter Solution: Powder Coating Repair and Refinishin

- WRNZ’s Proven Refinishing Proces

- Case Study: Powder Coating Repair at PwC Tower, Auckland

- Why Choose WRNZ for Powder Coating Repair in Auckland

- Restore, Don’t Replace

- Related Posts

When Powder Coating Doesn’t Last

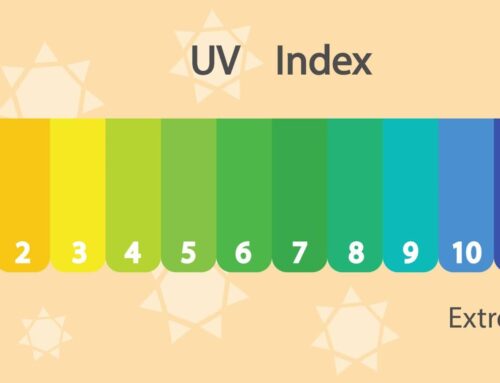

Powder coating is widely known for its durability, corrosion resistance, and attractive finish – but even the toughest coatings can fail over time. Constant exposure to UV rays, weather extremes, moisture, and physical wear can cause powder-coated surfaces to fade, peel, or chalk.

When this happens, many property owners assume their only option is full replacement. However, in most cases, WRNZ’s powder coating repair and refinishing services provide a far more efficient and sustainable solution. Using advanced on-site wet-spray systems, WRNZ restores faded or damaged powder-coated surfaces to a factory-grade finish – without the need for replacement.

Common Reasons Why Powder Coating Fails

Understanding what causes failure helps property owners make informed decisions about maintenance and restoration.

1. UV and Weather Exposure

Auckland’s climate – with strong UV rays, humidity, and salt-laden air – can cause powder coatings to fade, oxidise, or lose gloss.

2. Poor Surface Preparation

If the surface was not properly cleaned, blasted, or degreased before coating, adhesion issues can develop, leading to early peeling or bubbling.

3. Physical Damage

Impacts from tools, ladders, or general use can chip or scratch the surface, exposing bare metal and allowing corrosion to set in.

4. Chemical or Environmental Contamination

Exposure to industrial pollutants, salt spray, or harsh cleaning agents can accelerate coating degradation and discolouration.

5. Ageing and Breakdown

Even high-quality powder coatings eventually degrade after years of exposure. That’s when powder coating repair or refinishing becomes the most cost-effective way to restore performance and appearance.

The Smarter Solution: Powder Coating Repair and Refinishin

Traditional powder recoating involves removing panels, stripping old coatings, and reapplying the finish in a controlled oven environment. For architectural façades, aluminium joinery, and fixed installations, this process is impractical, expensive, and disruptive.

WRNZ provides a superior alternative through on-site powder coating refinishing. Using high-performance wet-spray systems, WRNZ restores damaged powder-coated surfaces without removal – replicating the look, texture, and durability of new powder coating.

Benefits of On-site Refinishing Over Powder Recoating

- No removal required: Ideal for installed façades, cladding, and joinery.

- Cost-effective: Avoids labour, transport, and dismantling costs.

- Minimal disruption: Work is completed efficiently on-site.

- Eco-friendly: Refinishing reduces material waste and carbon impact.

Long-lasting results: UV-resistant finishes maintain colour and protection for years.

WRNZ’s Proven Refinishing Proces

WRNZ’s process for powder coating repair and refinishing ensures lasting protection, perfect colour matching, and a flawless appearance.

Step 1: Detailed Assessment

The surface is inspected for corrosion, adhesion, and coating failure to determine the right restoration system.

Step 2: Preparation and Cleaning

All contaminants, oxidation, and loose material are removed to create a clean, bonded surface.

Step 3: Targeted Repairs

Damaged or corroded sections are treated and primed to restore the integrity of the underlying substrate.

Step 4: Precision Refinishing

Using advanced wet-spray techniques, WRNZ applies a protective coating that replicates the appearance and durability of new powder coating.

Step 5: Final Quality Check

Every refinished surface is inspected for adhesion, gloss consistency, and colour accuracy – ensuring a premium, long-lasting result.

Case Study: Powder Coating Repair at PwC Tower, Auckland

During the construction of the PwC Tower at Auckland’s Commercial Bay, numerous aluminium elements sustained powder coat damage through ongoing building activity and handling. WRNZ was engaged to perform powder coating repair and refinishing throughout the construction phase and up to project completion, ensuring all architectural finishes met specification for final handover.

Utilising advanced on-site refinishing and colour-matched wet-spray coating systems, WRNZ restored the affected joinery, façade elements, and internal architectural finishes to their original condition, achieving a consistent appearance across all surfaces.

All works were undertaken in coordination with the main contractor and other trades to maintain programme requirements and minimise disruption to site operations.

Result: Every coated surface was returned to as-new condition, meeting the strict aesthetic and performance standards required for architectural sign-off and building completion.

Why Choose WRNZ for Powder Coating Repair in Auckland

1. Over a Decade of Expertise

Since 2013, WRNZ has been restoring powder-coated aluminium, steel, and façade systems across Auckland’s skyline – from heritage buildings to modern high-rises.

2. Advanced Coating Technology

Our wet-spray refinishing system delivers a consistent, durable coating that matches or exceeds the performance of the original powder coat.

3. Sustainable and Low-Waste

By repairing and refinishing existing surfaces, WRNZ helps reduce landfill waste and the carbon footprint of architectural refurbishments.

4. Auckland-Based Specialists

We understand how local weather, UV intensity, and salt air affect coatings – and tailor every refinishing solution accordingly.

5. Seamless Integration

Projects are completed with minimal disruption, ensuring clients can continue operations while surfaces are transformed.

Restore, Don’t Replace

When your powder-coated surfaces begin to show signs of wear, you don’t need to start over. WRNZ’s powder coating repair and refinishing services can restore aluminium, steel, and architectural surfaces to their original look – or even improve upon it.

With over a decade of experience, advanced technology, and a reputation for precision, WRNZ remains Auckland’s trusted specialist in coating repair, recolouring, and restoration.