Auckland’s Harsh Climate: How Powder-Coated Facades Break Down Over Time

Auckland’s coastal environment is beautiful – but exceptionally harsh on exterior building materials. Commercial properties across the region endure constant exposure to UV radiation, salt-laden winds, humidity, and heavy rainfall. Over time, these conditions cause fading, chalking, corrosion, and visible surface failure on façades, cladding, and aluminium joinery that were originally powder coated during manufacturing.

Understanding how these environmental forces affect coating performance helps building owners plan proactive maintenance and extend the lifespan of architectural finishes.

Why Auckland’s Climate Causes Surface Damage

Auckland’s location between two harbours exposes buildings to a unique blend of environmental stressors that accelerate surface deterioration.

Key Environmental Stressors

Salt-laden winds

Salt deposits accumulate around joins and edges, allowing corrosion to form beneath ageing coatings.

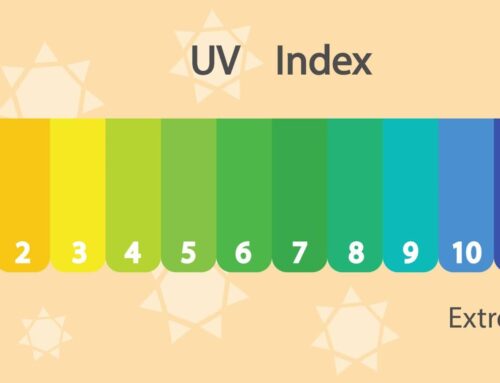

High UV exposure

Strong UV radiation breaks down the binder in powder-coated finishes, causing fading, chalking, and surface dullness.

Humidity & heavy rainfall

Moisture can creep into compromised coatings, leading to blistering or peeling over time.

Daily temperature shifts

Expansion and contraction stress older coatings, weakening adhesion and creating micro-cracks.

Even high-quality factory-applied powder coatings eventually degrade when exposed to these long-term conditions.

Common Signs of Powder-Coated Surface Failure

Across Auckland, buildings frequently display early signs of coating deterioration, including:

- Faded or uneven aluminium joinery

- Chalky, powdery residue on the surface

- Peeling, cracking, or blistering coatings

- Corrosion forming on exposed metal

- Weathered or patchy façade panels

Addressing these issues early prevents more extensive damage and avoids costly replacement of panels or joinery.

Why Powder-Coated Surfaces Cannot Be Re-Powder Coated On-Site

A common misconception is that faded or weathered powder-coated surfaces can simply be “powder coated again”.

In reality, powder coating requires:

- A controlled industrial environment

- Electrostatic application equipment

- A curing oven reaching 160–210°C

Since installed façades and fixed joinery cannot be removed and baked, on-site powder coating is not possible.

This is why modern refurbishment uses wet-spray architectural coating systems specifically engineered for on-site restoration of previously powder-coated substrates.

Modern On-Site Solutions for Refurbishing Powder-Coated Surfaces

Today’s restoration technologies allow buildings to be refinished on-site, without removing panels or joinery. These advanced wet-spray systems:

- Restore colour and surface integrity

- Improve UV and corrosion resistance

- Enhance building appearance

- Extend the lifespan of existing façades

- Reduce disruption and avoid costly replacements

- Provide durable architectural finishes suitable for New Zealand’s climate

This makes on-site restoration one of the most effective and sustainable maintenance strategies for commercial buildings.

WRNZ’s Expertise in Façade & Joinery Restoration

WRNZ specialises in restoring and refinishing surfaces that were originally powder coated, using high-performance wet-spray systems designed for architectural environments.

Our refurbishment services include:

- Repair and rejuvenation of weathered façades

- Recolouring and restoration of aluminium joinery

- In-situ application of long-life wet-spray coating systems

- Surface preparation, repairs, and corrosion treatment

- Refinishing ageing cladding, ACM panels, steelwork, and exterior architectural elements

These methods deliver a premium finish that performs exceptionally well in New Zealand’s coastal conditions – without requiring removal or factory processing.

Case Study: ACM Panel Refurbishment – Fisher & Paykel Lecture Theatres

WRNZ refurbished over 3,200m² of aluminium composite panels (ACM) at the University of Auckland’s Fisher & Paykel Lecture Theatres – a complex project involving extensive façade rejuvenation and flashing restoration.

Project Scope

- Full façade restoration

- Repair of ageing and oxidised ACM panels

- Rejuvenation of dull, weathered surfaces

- Restoration of aluminium flashings

- Work completed in an operational environment

Challenges

- Highly visible commercial frontage

- Large surface areas in exposed conditions

- Needed an in-situ solution without removing panels

- Strict durability and aesthetic requirements

Coating System Used

- High-performance wet-spray architectural system

- UV-stable, corrosion-resistant finish

- Multi-layer application for long-term durability

Results Achieved

- Uniform modern finish across all panels

- Complete rejuvenation of sun-damaged surfaces

- Longer-lasting protection against UV & coastal exposure

- Cost-effective alternative to full panel replacement

This project shows how aged powder-coated ACM panels can be successfully restored in situ, delivering long-term durability and a revitalised appearance.

Benefits of Refurbishing Instead of Replacing

Choosing refurbishment over replacement provides numerous advantages:

- Significant cost savings

- Minimal disruption compared to panel removal

- Sustainable by extending the life of existing materials

- Fast turnaround with premium architectural finishes

- Enhanced appearance without major structural work

In most Auckland environments, on-site restoration is the most efficient way to protect and extend the life of powder-coated façades and joinery.

Final Thoughts

Auckland’s coastal climate is tough on powder-coated façades and aluminium joinery. Over time, UV radiation, salt air, and moisture lead to fading, corrosion, and surface breakdown.

Modern wet-spray restoration systems provide an effective, durable, and sustainable solution to rejuvenate and protect these surfaces – without the need for replacement or factory powder coating.

Regular inspections and timely refurbishments help preserve both appearance and structural performance, ensuring buildings remain visually appealing and weather-resistant for years to come.